Profound and Detailed

2025-06-09

The concept of step response of pressure transmitter

The step response of a pressure transmitter refers to the change in the transmitter output signal over time when the input pressure suddenly changes from one stable value to another. This characteristic can intuitively reflect the transmitter's response speed, stability and accuracy to sudden pressure changes, and is an important indicator for evaluating the transmitter's dynamic performance.

The main parameters and meanings of step response

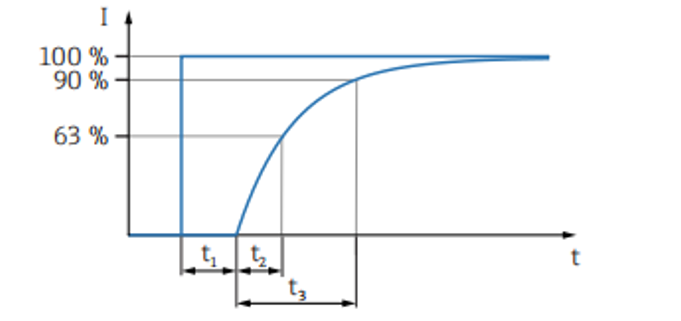

Delay time: The time required from a step change in input pressure to a perceptible change in the transmitter output signal. It reflects how quickly the transmitter begins to respond to pressure changes. For example, in some systems that require a quick response, such as aerospace pressure monitoring systems, if the delay time is too long, the critical early stages of pressure changes may be missed, leading to misjudgment of system status.

Rise time: The time required for the output signal to rise from 10% to 90% of the steady-state value. This parameter is mainly used to measure the ability of the transmitter to quickly increase the output signal when the input pressure suddenly increases, reflecting the transmitter's response speed to the pressure rise process. For example, in some chemical reactions, the pressure will rise rapidly when the reaction starts. A shorter rise time helps to capture the initial stage of the pressure change in time, thereby better monitoring and controlling the reaction process.

Step response time = delay time t1 + rise time t3

Step response characteristics of common pressure transmitters

Silicon piezoresistive pressure transmitter: It has the characteristics of small size, simple structure, high sensitivity, good dynamic response, etc. Its step response speed is relatively fast and it can track the rapid changes of pressure well. This is because its pressure sensitive element is based on the piezoresistive effect of semiconductor materials. When the pressure changes, the resistance value of the diffusion resistor can change rapidly, so that the output signal can respond quickly to the step change of pressure.

Capacitive pressure transmitter: uses differential capacitance as the detection element, and has the characteristics of high precision, high stability and high reliability. Its step response is relatively stable, and the overshoot is usually small, but the rise time may be relatively long. This is because the change in capacitance takes a certain amount of time to reach a stable value, but once it reaches stability, the accuracy and stability of its output signal are high.

Factors Affecting Step Response

Mechanical properties of the sensor: The mechanical properties of the sensor part of the pressure transmitter, such as the diaphragm, bellows and other elastic sensitive elements, have a great influence on the step response. If the mass of the elastic sensitive element is large, its inertia will cause the response to slow down, increase the delay time and rise time. For example, a heavier diaphragm takes more time to deform when the pressure changes step, which will delay and slowly rise the output signal of the transmitter.

Time constant and damping characteristics of internal circuits: The circuits inside the transmitter, such as signal amplification circuits and filter circuits, have certain time constants and damping characteristics. A larger circuit time constant will cause the signal change to lag and affect the response speed. The damping characteristics determine whether the output signal will oscillate and the degree of oscillation. If the damping is too small, it is easy to have a large overshoot and long-term oscillation; if the damping is too large, it may cause the response to be too slow.

Energy transfer efficiency between sensor and medium: The energy transfer efficiency between sensor and measured medium will also affect the step response. For example, when there is an air gap or poor coupling between the medium and the sensor diaphragm, the pressure transfer will be delayed, so that the transmitter cannot sense the step change of pressure in time. In addition, the viscosity and other characteristics of the medium will also affect the energy transfer speed. A medium with high viscosity may slow down the sensor's response to pressure changes.

Monocrystalline silicon pressure transmitter

Microcyber's monocrystalline silicon pressure transmitter uses a monocrystalline silicon piezoresistive pressure sensor with a built-in high-resolution ADC, which can provide a step effect of up to 250ms (different ranges will have certain differences), meeting the more stringent working conditions on site.

Some performance indicators of the monocrystalline silicon pressure transmitter are as follows:

· Support the latest versions of HART, FF H1, PROFIBUS PA, and PROFIBUS DP protocols,

· Pass the HART, FF, PA, and DP interoperability certification tests.

· Pressure types include: gauge pressure, absolute pressure, and differential pressure.

· Highest accuracy: ±0.075% full scale (20℃℃, range ratio 10:1 range)

· Long-term stability: ±0.2% range upper limit/5 years.

Industrial Internet Access Point

Microcyber is committed to the research and development, production, sales and integrated application of industrial IoT products.

Microcyber is the first fieldbus protocol stack in China and the third in the world to pass international certification, the first fieldbus instrument in China to pass international certification, the first demonstration application of networked control system in China, and the first function in China to pass international certification, the first wireless HART product in China to pass international certification, etc.

Microcyber is one of the main undertaking units of important national science and technology projects in the fields of industrial Internet of Things and industrial automation. Over the years, we had undertaken a number of major national science and technology projects, the National High Technology Research and Development Plan (863 Plan), and the development of intelligent manufacturing equipment. Special projects and other national science and technology plans.

Microcyber has accumulated rich experience in technical capabilities, technical achievements and technical reserves, and has a strong R&D team to protect the sustainable development of the company's products.

<< Previous page

Next page >>